Window cells are integral parts of a window’s frame. You can choose to make them out of various materials depending on your requirements and the aesthetic you wish to achieve.

Window cells can also be constructed out of natural wood, which is an attractive material suitable for any room.

Types

Window cells come in many varieties, so it’s essential to understand their differences. Additionally, the material of construction plays an integral role in both cost and functionality; having the correct material for your application ensures a long-lasting and enjoyable product experience for customers.

Wood is the most common and obvious option when selecting a building material. Popular species include pine and fir, with the latter being more durable against elements. When choosing colors for your wood, consider what type of stain best matches its quality; color can make an enormous difference in overall aesthetic if living in an older house with many wood elements or using stain on new construction. A quality paint job can make all the difference in appearance as well, especially if your residence boasts many wooden elements.

Start your window installation journey with a professional window installer who can recommend the most suitable options for your home or business. It is essential to identify your needs and budget before finding the ideal option for you. A reliable specialist not only explains all of the details of new windows but also assists with selecting materials and finishes suitable for your new residence or office.

Materials

When building a new home or replacing existing windows, it’s essential to select the appropriate materials for your window cell. Choose something that will stand up against elements, require minimal upkeep and look great over time. Furthermore, ensure the material you select is energy efficient and environmentally friendly.

Aluminum is a popular material for window frames due to its light weight, durability and ease of upkeep. Its slim shape and contemporary aesthetic make it suitable for many styles of architecture.

Fiberglass is an excellent material for windows due to its remarkable versatility and strength. It can support large picture windows as well as double-paned ones, and you can paint it to match your style. Furthermore, fiberglass is impervious to weathering, rot, decay, insects, salt air and ultraviolet rays – making it the ideal material for window construction.

Wood is an elegant and traditional choice for windows that’s cost-effective to paint. It also makes a popular exterior door material due to its strength and beauty in the elements.

It’s an ideal choice for windows that get hot in the summertime, since the film will block out solar heat and keep your indoor air cooler. Unfortunately, it is susceptible to water damage and staining if not taken care of properly.

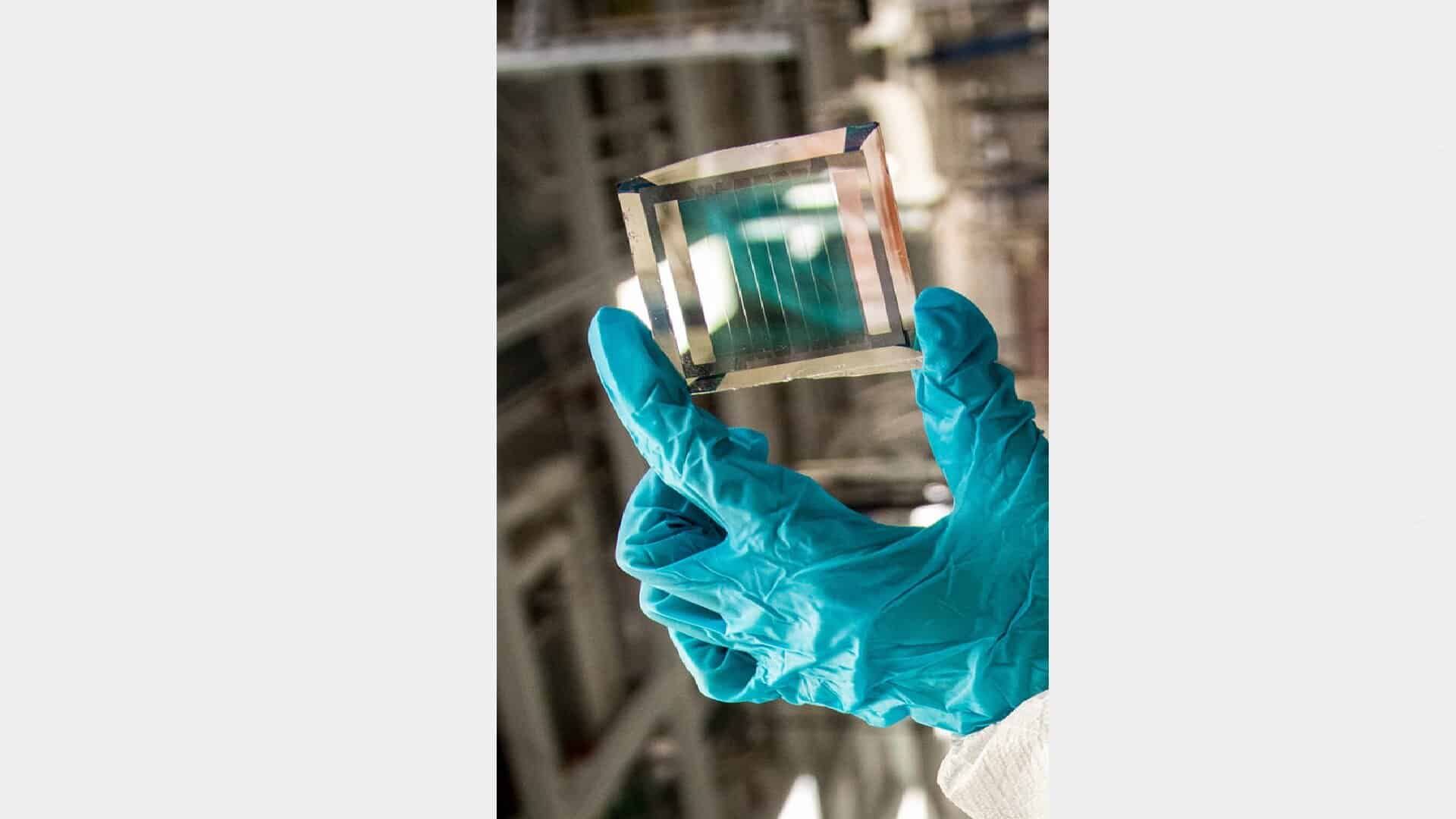

Window cells, which darken when an electrical field is applied, operate similarly to batteries. Now X-ray studies at SLAC have given researchers a detailed insight into how this color-changing material behaves within an actual battery.

Researchers have recently discovered that certain chemical components, some of which may be overlooked, have an important impact on how efficiently windows generate electricity. This finding could bring cities closer to their goal of becoming energy sustainable.

Window cell designs in the latest generation absorb about half of visible light that a standard glass panel can and use it for powering their electronics. By cutting back on energy consumption associated with providing electricity to buildings, these window cells could significantly reduce greenhouse gas emissions.

Installation

If you plan to install a window cell, it is essential that all necessary steps be taken. Otherwise, the unit may not function optimally and could even lead to leaks in your home. Furthermore, make sure all parts are in excellent condition and of consistent quality.

Begin by measuring and marking the inside of window jambs to create a reveal line, where head casing and side casing will meet. Use this measurement as reference point for determining sill width; then cut side casing to that size using either a miter saw or miter box.

Now you can use either a hammer and nail or pneumatic nailer to fasten the side jambs into the framing. Often, you may need to push the center of the jambs in slightly in order to guarantee they are square.

Once the jambs are installed, you can install the head casing at the top of the window. To do this, measure between two miter points on either side and cut a square crosscut at those locations on the head casing. With minimal gap, fit it over both head jambs and into the wall.

Test-fit the corner blocks at both corners to confirm they’re flush with the bottom edge of the head casing. Finally, use wood filler to fill any gaps around the edges of both jambs and casing that can be seen from outside.

Finally, use a hammer to secure the head casing onto the top of the window jamb. Repeat this process on both sides of the window.

For extra security, Marvin windows recommend using Dupont FlexWrap as a window seal. This flexible plastic material provides maximum flexibility.

If your window doesn’t have a nailing flange, pressure-sensitive flashing tape can be used to seal the area between the sash and wall. This tape is made of an adhesive material that will adhere to both surfaces – protecting them against water infiltration and mold growth.

Maintenance

Window cell windows require some upkeep to keep them looking their best. Like other window types, they’re prone to dirt and exposure from external elements; therefore, regular cleaning is necessary in order to eliminate bugs and debris buildup.

Though there’s no one-size-fits all maintenance routine for window cell windows, it is recommended to inspect and maintain them at least once annually to keep your home looking its best. One important task is cleaning out the wells; this simple task eliminates dust, leaves, and other potential hazards which could damage the glass. Doing this small job now could prevent bigger issues in the future such as water damage to ceiling or wallboards, broken windows or mold growth.

A more sophisticated method involves using a vacuum cleaner to eliminate stubborn dirt. You could also try employing a wet/dry vacuum cleaner if the dirt won’t come off with just damp cloths and elbow grease.