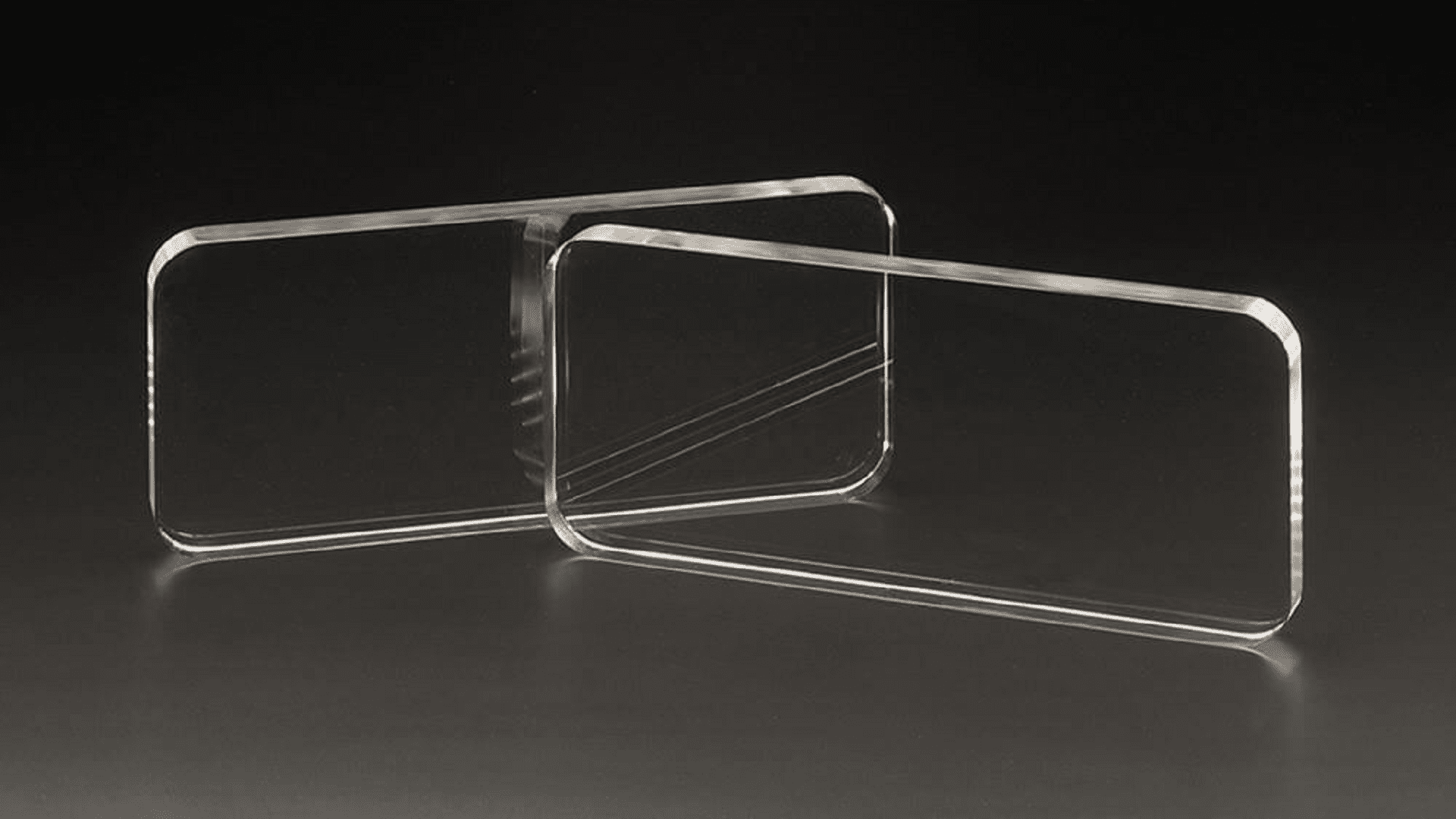

Fused silica glass is an optically transparent for windows, non-hygroscopic material used in many applications. It’s chemically inert, resistant to corrosives and water, as well as thermal shock-resistant.

Fused silica glass, despite its purity, can contain impurities that may affect its properties. These include metals (Al, Fe, and Na), OH groups and trace amounts of water.

Quartz vs. fused silica

Quartz is the primary form in which silica naturally occurs; it’s an opaque crystalline mineral that makes up a substantial part of Earth’s crust. Quartz primarily consists of silica (silver dioxide) but also contains naturally occurring impurities in various proportions.

Some samples contain trace amounts of iron and copper oxides. Furthermore, boron and magnesium oxides may be detected as ions within silica crystals.

Quartz crystals possess a unique crystal structure which gives it its special properties and make it ideal for certain applications, such as quartz crystal oscillators in electronic systems and wristwatches.

Quartz has a very low thermal expansion coefficient compared to other glasses, making it highly sought-after in many applications. Furthermore, due to its chemical inertness, it can be utilized in producing refractory shapes for various high-temperature thermal processes like steelmaking or investment casting.

Fused silica is an amorphous glass chemically similar to quartz with unique thermal, mechanical, and electrical properties. It finds widespread industrial uses such as sheathed electric elements in room heaters and furnaces.

Its low thermal expansion coefficient and refractory properties allow it to be rapidly heated and cooled with little risk of breakage while being chemically resistant to most acidic compounds – making it an ideal choice for many applications in the energy industry.

Fused silica is an ideal optical material for ultraviolet lasers and imaging applications due to its high transmittance in the UV range, which makes it ideal for these applications.

Due to its amorphous structure, fused silica is much less prone to microcracking than glass, which is critical in applications where even minor cracks can lead to major issues.

The exact location of the absorption edge is highly dependent on the quality of fused silica, including any trace impurities and potential hydroxyl molecules formed during devitrification. Ideally, OH content should never exceed 10 ppm for IR-grade materials to be effective.

Properties

Fused silica is an optical, thermal, and mechanical glass made of silicon dioxide. While it’s the purest form of silica available, it can be modified with various additives to enhance its optical, thermal, and mechanical characteristics.

Its low dielectric constant makes it an ideal material for optical components and devices. Furthermore, its high thermal shock resistance makes it suitable for use in chemical and pharmaceutical manufacturing operations where it can withstand high temperatures, corrosive chemicals, as well as water.

Fused silica has properties that are determined by the manufacturing process. Both the type and quality of raw material can significantly influence its performance.

One important characteristic of fused silica is its amorphous structure. This means it contains many hydroxyl molecules, which can degrade IR light transmission. Therefore, when selecting an IR-grade glass for use in laser applications, make sure it contains less than 10 ppm hydroxyl content.

Another noteworthy property of fused silica is its resistance to most acids. This makes it ideal for medical and biomedical applications, as well as shielding and coating semiconductor devices.

Glass is extremely strong when compressed due to the high strength of silicon dioxide crystals within it. Unfortunately, under tension, this tensile strength may be greatly diminished by surface flaws such as microcracks or scratches.

Particularly with fused silica that has been machined or fabricated, its strength depends on the manufacturing process and how many surface flaws have been created during that process.

It is essential to remember that the crystal structure of a material can degrade when exposed to UV radiation. Therefore, selecting an IR-grade fused silica with low levels of hydroxyl and stable in the ultraviolet range is key.

Applications

Fused silica glass is an incredibly strong material that can withstand harsh conditions. It’s used in the fabrication of parts and components for various high-tech applications like optical and medical devices.

Quartz is an earthen mineral composed of silicon and oxygen that forms naturally in many types of rocks throughout the Earth’s crust. Through a heat flux process, this mineral can be transformed into the glass for use as decoration.

Glass can be shaped into a variety of shapes and sizes, making it suitable for many uses. Furthermore, the material is highly durable and resistant to extreme temperatures as well as corrosive chemicals.

Though it has many uses, the optical industry primarily relies on it. It is commonly employed to manufacture lenses, prisms, diffraction gratings, and other optical components.

This glass is highly reflective across a broad spectral range, from near-infrared to ultraviolet. However, it’s content of hydroxyl (OH) molecules makes it susceptible to absorption in the IR.

Fused silica glass offers an expansive spectral range and chemical inertness, making it suitable for window applications in harsh environments as well as laboratory tools exposed to caustic compounds.

Ceramics can be produced in a controlled environment and have greater stability than metals. Additionally, it makes an excellent material for machining operations with the added bonus of being able to lap and polish to an impressive shine.

Fused silica is often employed in the production of glass components for various applications, such as solar cells and photovoltaic panels. It features a low coefficient of thermal expansion and transparency across a broad spectrum of light.

Therefore, it is an ideal material for many optics and laser applications. Furthermore, it can be employed to create a protective layer on semiconductors.

Fused silica can be formed into various parts and components, such as glass prisms and diffraction gratings. It also makes excellent optical windows for telescope mirrors or photomasks.

Manufacturing

Fused silica glass is an optically clear, chemically inert material with excellent temperature strength. It’s widely used to fabricate lenses, prisms, optical flats, mirror substrates, and diffraction gratings due to its broad spectral transmission range, hardness, and low thermal expansion rate.

Fused silica glass is created by combining silicon dioxide (SiO2) with various impurities. Due to its higher working temperature than traditional glass, fused silica tends to be more expensive than float glass. Furthermore, this commercial glass offers additional properties and uses not found in other commercial glasses such as its low dielectric constant, superior ultraviolet (UV) transmission, and strong resistance to most acids (with the notable exception of hydrofluoric acid).

Furthermore, it has an incredible resistance to fire and most types of plasmas, making it the ideal material for applications requiring high thermal stability such as photolithography substrates or etched microwave circuits.

Photomasks require strong materials with excellent tensile strengths of at least 1.1 x 109 Pa, though this number may be reduced due to surface flaws or manufacturing process issues.

Fused silica manufacturing is an intricate process requiring extensive experience and special expertise. After cooling and annealing the glass, it must expand without crystallizing. Furthermore, heat must be evenly distributed throughout its thickness for a successful production.

This process takes time, and the end product may contain microcracks or other imperfections. As these defects reduce fused silica’s tensile strength, it is best to avoid them.

Fused silica can be manufactured in several ways. One popular process uses silicon tetrachloride, added to a hydrogen-oxygen flame. This creates a glass with high purity and improved deep ultraviolet transmission but it also produces by-products such as chlorine and hydrochloric acid. To avoid these unwanted by-products, new methods have been developed that utilize alternative raw materials.